MAS 863: How to Make (Almost) Anything

As an overview of the entire term, I selected one picture for each weekly project. While everyone was trying to help by giving suggestions about how to improve the fab class at the last class, I just wanted to tell Neil that "How to Make Almost Anything" makes me get to know what MIT means.

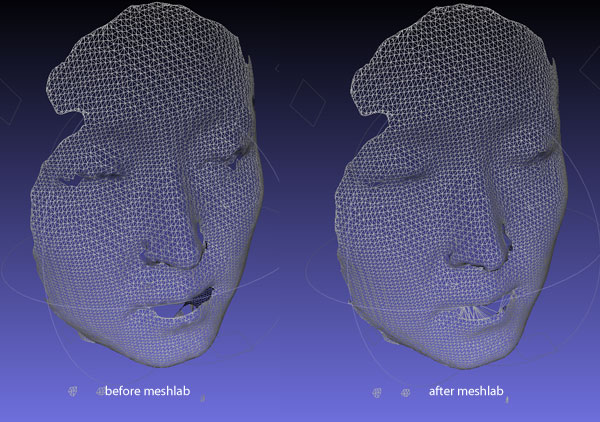

To quickly conclude, several things I leant all through the semester:

1. almost all the old or new machines

2. don't dare to play with any tools and machines

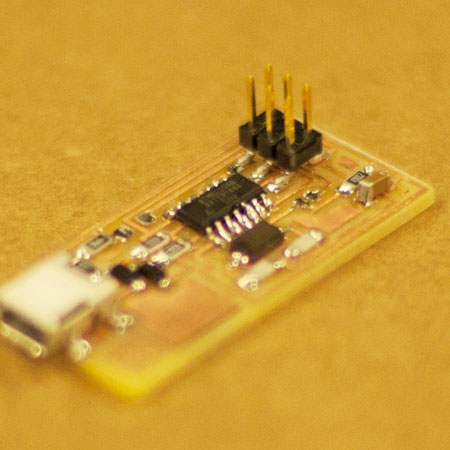

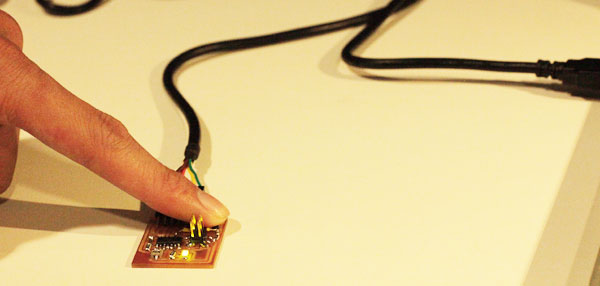

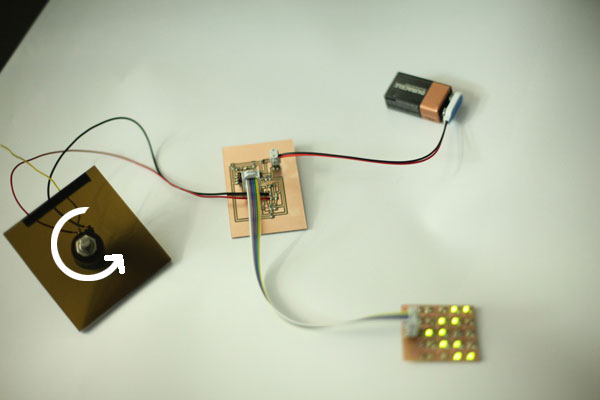

3. work like a real electrical engineer from time to time

4. repect the communication of knowledge and skills

5. exciting about making, and respect making culture

6. learn to write tutorials and document things

7. get an experience you will never forget for an entire lifetime.

I got the screenshot of final openhouse pics from David's Flikr album.

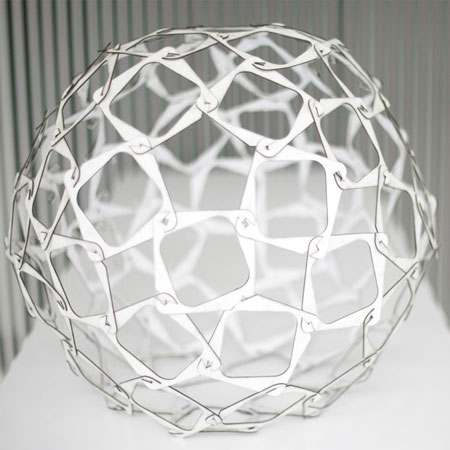

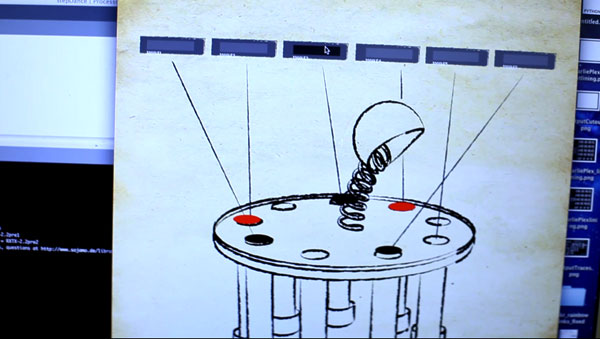

The ball is made of 60 pieces of squares. All the squares have the same size and cut. It doesn't need to be holo in the middle. A cut ismade in each corner to join the two corners from two connected squares.